The Power of Prepreg Carbon Fiber:

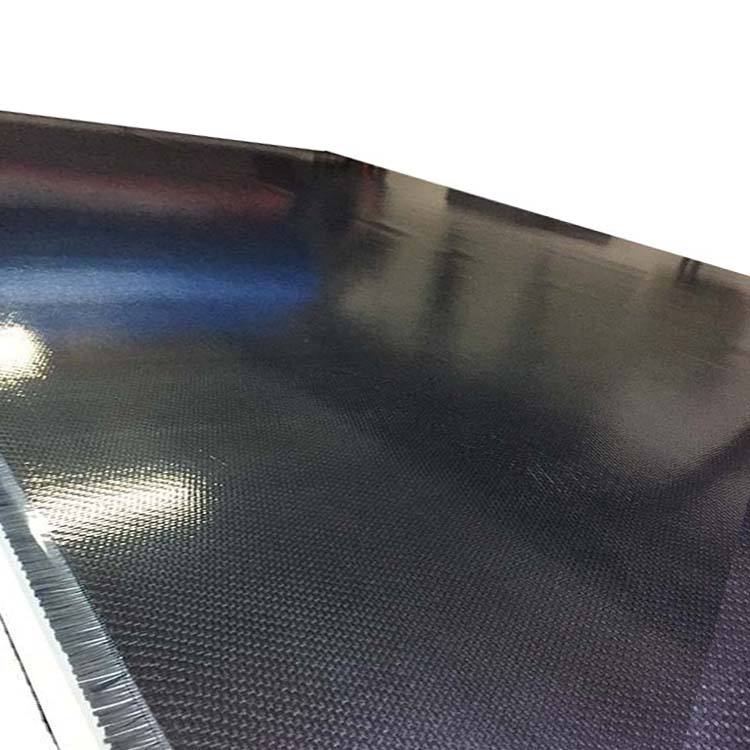

What is Prepreg Carbon Fiber? Prepreg carbon fiber refers to carbon fiber sheets or fabrics that are pre-impregnated with resin. The resin is typically an epoxy-based material that is partially cured, ensuring consistent resin-to-fiber ratios and optimal impregnation. This eliminates the need for manual resin application during composite manufacturing.

Exceptional Strength-to-Weight Ratio: Prepreg carbon fiber composites possess an extraordinary strength-to-weight ratio, surpassing traditional materials like steel and aluminum. This makes them ideal for applications where weight reduction is crucial without compromising structural integrity, such as in aerospace components and high-performance automotive parts.

Customizable and Tailored Properties: Prepreg carbon fiber allows for precise control over fiber orientation, resin content, and thickness, enabling manufacturers to tailor the material's mechanical properties to specific application requirements. This customization facilitates the production of high-performance parts with enhanced stiffness, impact resistance, and fatigue life.

Enhanced Manufacturing Efficiency: The prepreg carbon fiber manufacturing process streamlines production by eliminating the need for manual resin application. This reduces labor costs and ensures consistent resin distribution throughout the composite, resulting in improved quality and repeatability.

Applications of Prepreg Carbon Fiber:

Aerospace Industry: Prepreg carbon fiber composites are extensively used in the aerospace industry for manufacturing aircraft components, including wings, fuselages, and interior structures. Their exceptional strength and lightweight nature contribute to fuel efficiency, increased payload capacity, and improved performance.

Automotive Sector: In the automotive sector, prepreg carbon fiber finds applications in high-performance vehicles, luxury cars, and racing cars. From body panels to chassis components, the use of prepreg carbon fiber contributes to weight reduction, improved handling, and increased energy efficiency.

Sports and Recreation: Prepreg carbon fiber is utilized in various sports and recreational equipment, including bicycles, tennis rackets, hockey sticks, and golf clubs. The lightweight and high strength of prepreg carbon fiber enhance performance, enabling athletes to achieve greater speed, accuracy, and control.

Conclusion: Prepreg carbon fiber is a game-changer in the world of composite materials, offering exceptional strength, lightweight properties, and tailorability. Its applications span across industries, from aerospace and automotive to sports and recreation. As technology advances, the use of prepreg carbon fiber will continue to evolve, pushing boundaries and unlocking new possibilities for high-performance and sustainable solutions.